Design Procedure:

The design of transformer procedure is given here.

- Step-1: Inputs required for starting the design of transformer are: primary and secondary voltages, power rating, transformer efficiency and switching frequency.

- Primary Voltage, Ep=400 V

- Secondary Voltage, Es=800 V

- Output Power, Po=10 kW

- Frequency, fs=100 kHz

- Transformer efficiency, η=97%

- Step-2: Calculate the VA rating of transformer with power rating and its efficiency.

Step-3: Calculate the area product (AP) for the selction of core using the equation. It is a product of window (AW) and cross-sectional (AE) areas of core.

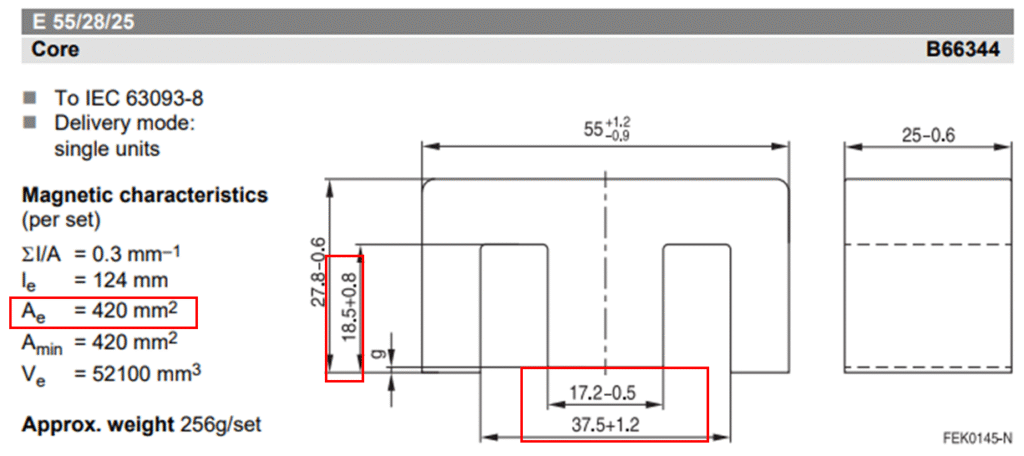

- Step-4: Choose a core and calculate the ‘AP’ using AW and AE values from datasheet.

From core data sheet, AE is directly available

AE = 420 mm2

Window area can be calculated using core dimensions

AW = (37.5 – 17.2) * 18.5 = 375.5 mm2

AP = AE * AW = 420 * 375.5 = 1,57,731 mm2

- Step-5: The selected core area product should be greater than the calculated area product.

AP of core (1,57,731 mm2) > calculated AP (1,54,650 mm2)

- Step-6: Calculate the primary side number of turns those required to wind on the core.

- Step-7: Calculate the secondary side number of turns using voltage relation

- Step-8: Calcluate the cros-sectional area that required to choose the wire

- The primary and secondary currents can be calculated using power and voltages respectively,

The crosssectional areas of wire required in primary and secondary can be calculated,

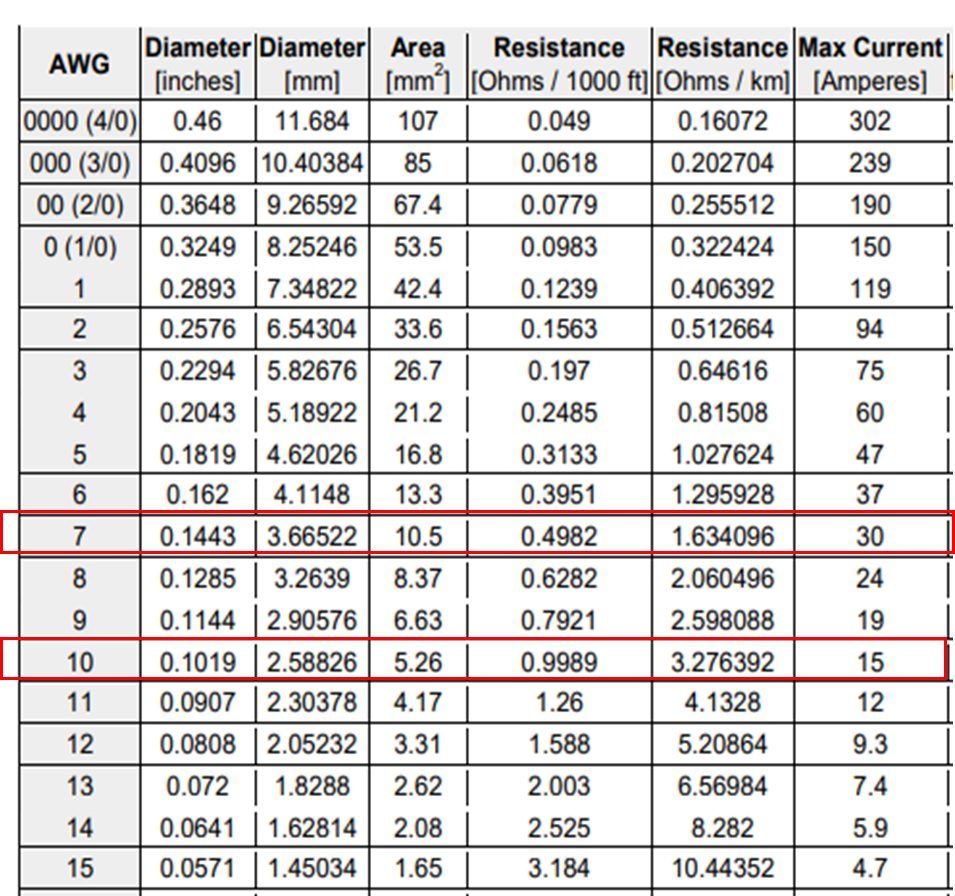

- Step-9: Choose a wire such that its cross-sectional should be more than the calculated cross-sectional area from previous step.

From AWG sheet,

awp = 10.5 mm2 @ 30 A

aws = 5.26 mm2 @ 15 A

primary wire awp (10.5 mm2) > calculated awp (8.56 mm2) &

secondary wire aws (5.26 mm2) > calculated aws (4.26 mm2)

Cross Checking Selected Core:

- Step-10: Cross-check the selcted core is suitable to wind the selected wire for calaculated number of truns. If not, choose the another core with next highest AP value and repeate the process from step-4

- Available core window area, KW . AW = 0.4*375.5 mm2 = 150.2 mm2

- Actual required window area, N1.awp+N2.aws = 9*10.5+18*5.26 = 189.18 mm2

The available window area (150.2 mm2) < actual (189.18 mm2)

Therefore, the selected core is not suitable, select a core with more dimensions which has AP slightly more than the currrent one.

Leave a Reply